Latest insights from G&O Bioreactors

Latest news

-

Chlorine harms marine life – and we don’t even need it

-

A solution for every challenge

-

Biological Wastewater Treatment: Marine Sewage Management

-

Welcome to G&O Bioreactors

-

Retrofitting Offshore Wastewater Treatment Plants: A Case Study in Offshore Operations

-

Understanding the long-term value of marine wastewater systems

-

Certification Highlights G&O Membrane Bioreactor Contribution to Cleaner Marine Environments

-

STP Solupak recommendation

-

Danish marine bioreactor to reduce harmful waste in oceans

-

Case: Fehmarnbelt Tunnel

-

Introduction to Wastewater Treatment Processes

-

The importance of biological water treatment

-

Case: A2SEA Challenger, helping a customer with a fast solution to their problem

-

Case: G&O Bioreactor Split Unit

-

G&O Bioreactor for Indian Research Station in South Pole

-

Clean Sailing: From Black Water to Clean Water

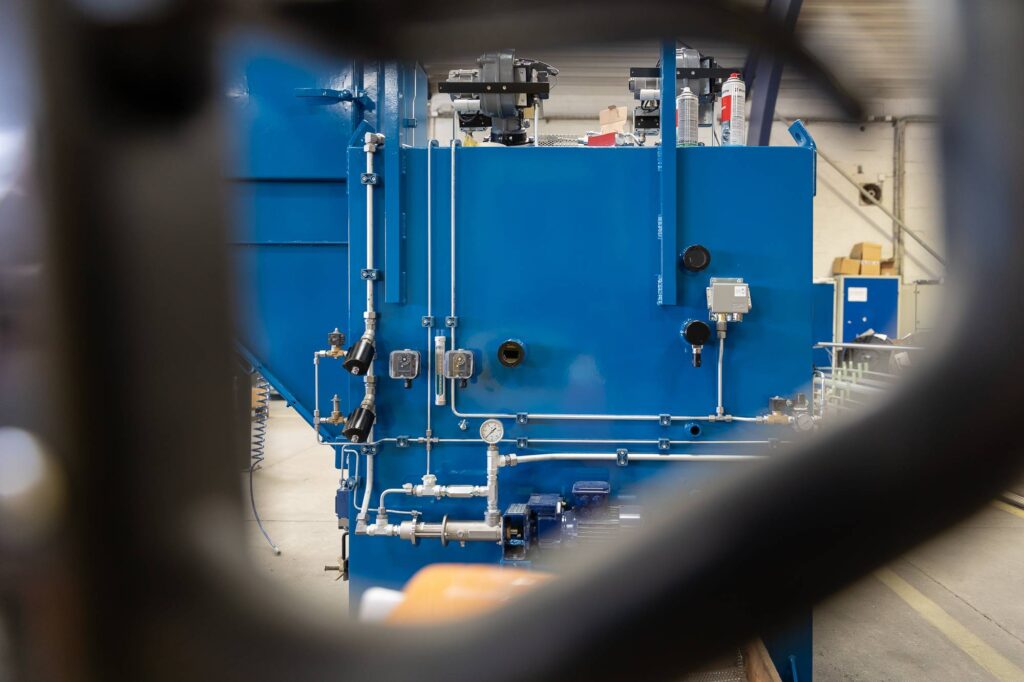

Look inside our production facilities

Our approach to R&D

In Gertsen & Olufsen, we have a long history of developing high quality solutions for the maritime industry.

Building on our heritage and inhouse competencies, we are continuously innovating with new product developments while adapting to the green transition.

We develop and improve products based on four principles

We strive to reduce the carbon footprint of the product throughout its life cycle

With our products, we want to contribute to actively reducing our customers’ carbon footprints

Our products should be easy to operate and maintain

Our products can be produced and delivered while reducing most possible time, material, cost and emissions