G&O Bioreactors

Products

Explore our full range of marine wastewater treatment systems and cleaning solutions.

From conventional and advanced bioreactors to specialised cleaning agents, G&O Bioreactors delivers sustainable technologies that ensure compliance, protect the marine environment and optimise your onboard wastewater operations.

Bioreactors

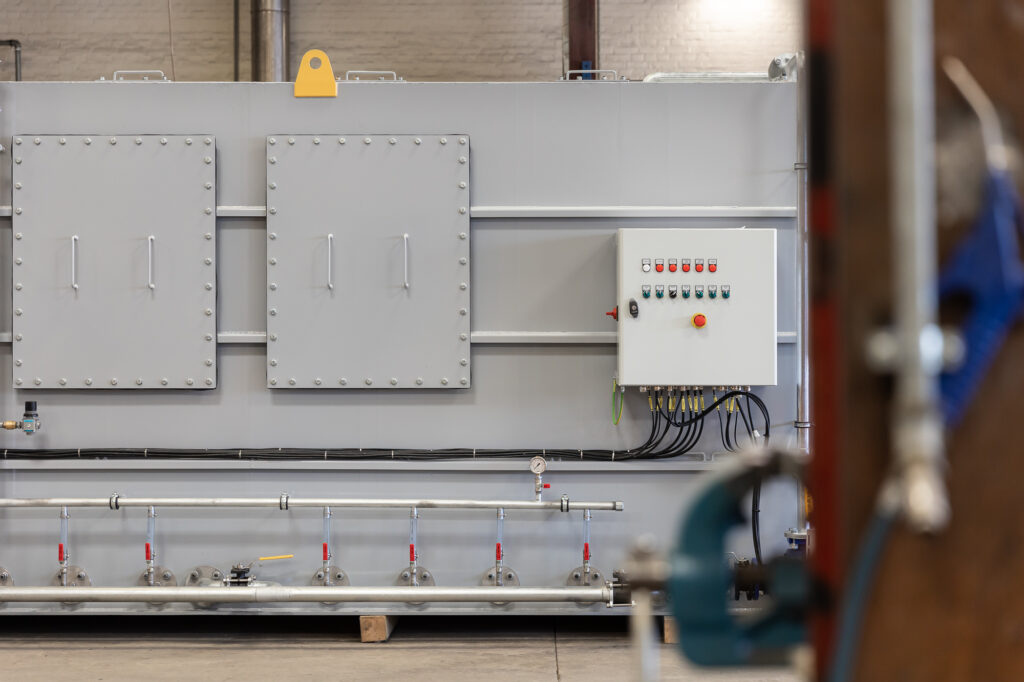

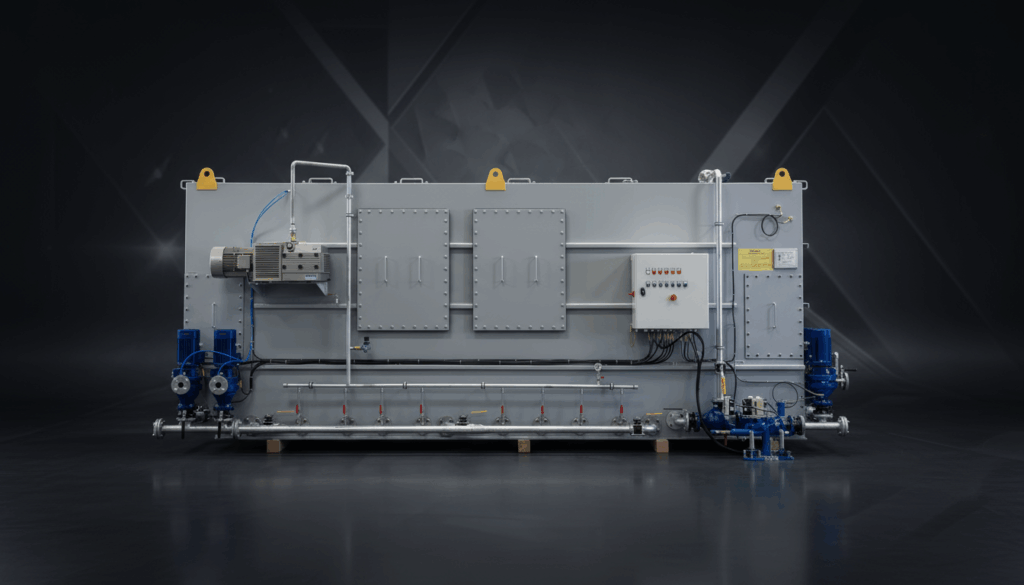

Conventional bioreactor

A fully biological system that treats black and grey water without chemicals, filters or dilution. Designed for easy operation and low maintenance, the G&O Conventional Bioreactor uses fixed biofilm and UV disinfection to ensure IMO compliance and E.coli removal. Ideal for both new builds and retrofits – with flexible configurations for any installation.

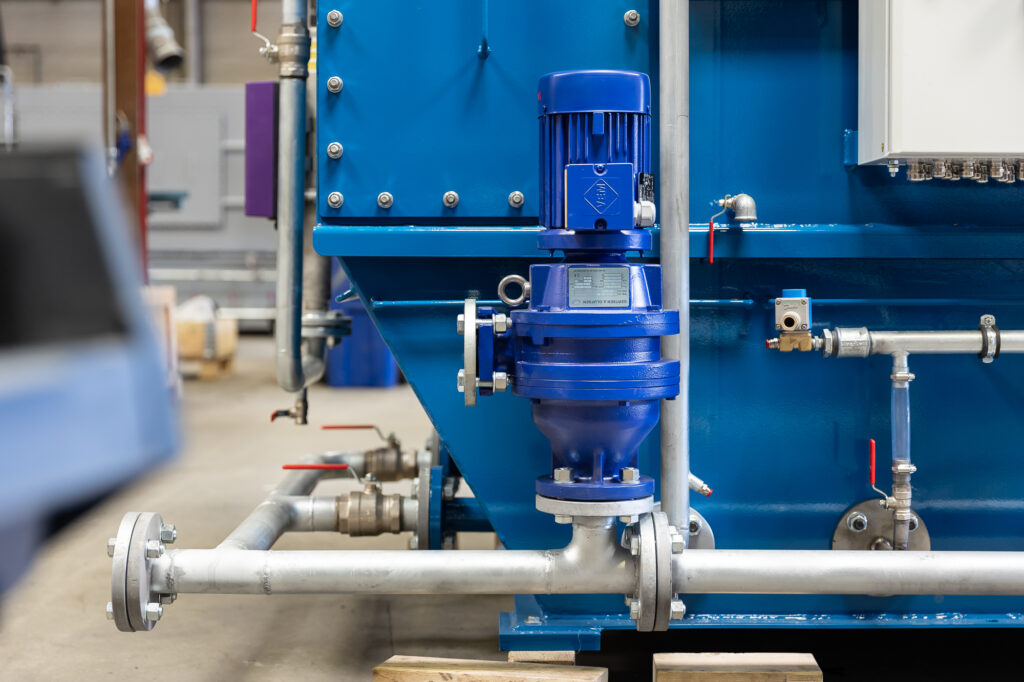

Advanced bioreactor

Combining biological treatment with ultrafiltration membranes, the G&O Advanced Bioreactor removes E.coli, phosphorus, nitrogen and microplastics — exceeding IMO MEPC 227(64) discharge requirements. Ideal for vessels operating in sensitive or regulated waters, this compact, chemical-free system delivers best-in-class effluent quality with low maintenance and minimal footprint.

Cleaning and maintenance

STP Solupak

STP SoluPak contains pre-measured, water-soluble sachets designed for safe and consistent dosing in marine wastewater systems. It supports odour control, reduces biofilm, and optimises biological treatment performance – fully compatible with G&O Bioreactors and safe for crew handling.

LA 20

LA-20 is a biodegradable liquid agent formulated to boost microbial activity in black and grey water treatment. Ideal for low-load conditions or systems under stress, it supports odour reduction and consistent system performance – without affecting biological balance.

ARC 360

ARC 360 removes calcium deposits, urine scale and other build-up in marine sewage systems. Safe for use with G&O Bioreactors, it prolongs system life and ensures optimal flow conditions – without damaging components or requiring system downtime.

What is grey and black waste water?

Grey water

Grey waste water from the vessel is all the water that comes from sinks, showers, cleaning, cooking etc.

Black water

Black waste water from the vessel is all the water that comes from toilets and medical treatments.

How does a membrane bioreactor work?

Learn how ultrafiltration and biological degradation deliver high-performance marine wastewater treatment with no need for chemicals.

→ Explore the technology

We deliver biological waste water treatment solutions for the maritime industry. We can treat both grey and black water before it is let out into the ocean. Our bioreactors live up to all rules and requirements, securing you operational flexibility while you protect marine eco systems where you operate.

We can deliver auxiliary solutions or connect with existing systems

Grease separating units

A well dimensioned grease separation is essential for a well functioning water treatment system for both black and grey water. Besides reducing the organic load of the treatment plant, it also prevents grease from building up in the vessel tanks and piping.

Vacuum collection solutions

The majority of our treatment systems are delivered with a G&O vacuum collection integrated into the system control and structure.

Sludge handling solutions

Sludge handling procedures will become a requirement in future marine regulations. We can dewater the sludge to minimise the volume of tanks required for storing sludge, returning water to the sewage treatment plant for processing before discharge.

Sludge can be incinerated or disposed as solid waste.

Customer case

A2SEA Challengers story

Off the mainland coast, an offshore construction vessel, A2SEA’s Sea Challenger, found itself to have met the capacity of its biological sewage treatment plant. A four-month project caused an increase in personnel on board the vessel and meant a quick solution for waste water treatment was needed.

Related brands – Waste & waste management