Membrane bioreactor for wastewater treatment in marine applications

As regulatory pressure on marine wastewater discharge increases, shipowners require robust, future-proof solutions for biological wastewater treatment. Traditional Moving Bed Biofilm Reactor (MBBR) systems have been widely used, but the membrane bioreactor process (MBR) offers significant advantages in terms of discharge quality and operational safety.

How a membrane bioreactor works

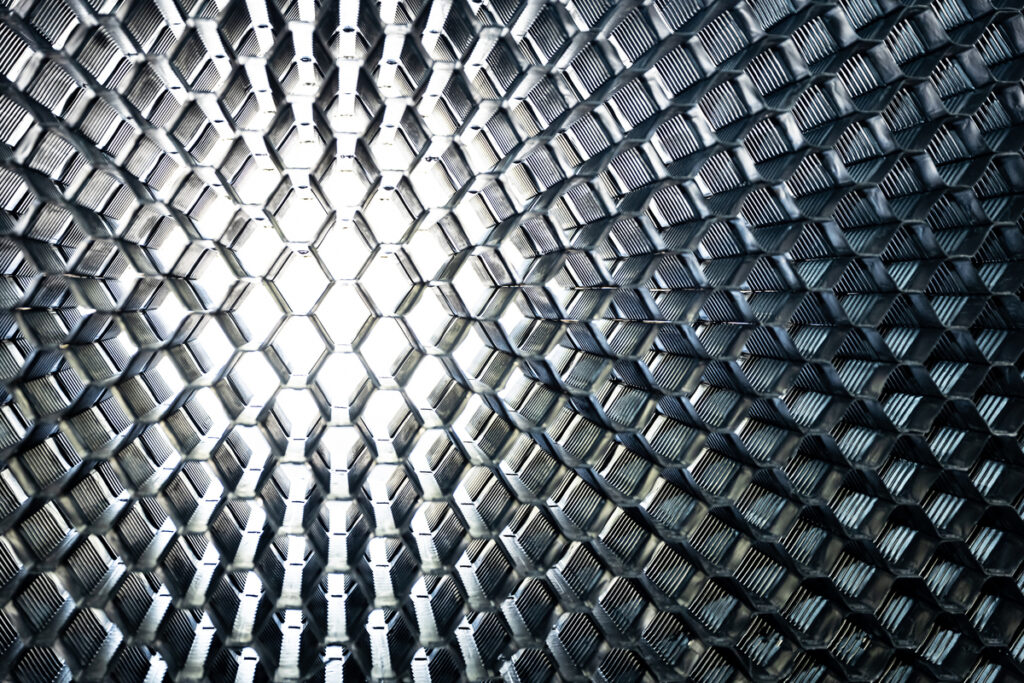

At its core, a membrane bioreactor combines conventional activated sludge treatment with membrane filtration. Micro-organisms break down organic content, and the resulting effluent is pressed through semi-permeable membranes, producing clear and bacteria-free treated water. The membrane bioreactor process physically separates solids and pathogens, allowing for direct discharge or reuse in accordance with the strictest IMO and MARPOL guidelines.

Membranes vs. MBBR – what are the advantages?

MBR vs. MBBR – Key Differences

Feature | Membrane Bioreactor (MBR) | Moving Bed Biofilm Reactor (MBBR) |

Discharge quality |

Very high – removes suspended solids, pathogens, nutrients, and microplastics |

Moderate – may not reliably remove nutrients or microplastics |

Regulatory compliance |

Fully compliant with IMO MEPC.227(64), incl. Special Areas |

Compliance may be challenged under stricter or future regulations |

Footprint |

Compact – biological treatment and filtration in one tank |

Larger – requires separate clarification units |

Operational stability |

Stable under fluctuating loads and variable influent |

More sensitive to influent quality changes |

Chemical use |

Minimal – little or no need for coagulants/flocculants |

Often requires chemicals for clarification |

Environmental impact |

No microplastic discharge; environmentally safe effluent |

Risk of microplastic release from plastic carriers |

OPEX / Maintenance |

Lower in long-term due to stable performance and fewer consumables |

Higher risk of operational interruptions; consumables and chemicals add costs |

Compare G&O’s MBR Systems

Interested in cleaner discharge and lower environmental risk? Compare G&O’s membrane bioreactor systems to discover how your operations can benefit from advanced treatment performance, regulatory peace of mind, and competitive lifecycle costs. Explore our Advanced bioreactor solutions.