Membrane Bioreactor systems: Compact, compliant and built for demanding marine environments

This technical article outlines the membrane bioreactor (MBR) system technology, how it functions, and why it represents a significant advancement over conventional marine wastewater treatment systems. The text explores core design features, performance differentiators, and the engineering rationale behind G&O’s MBR solutions. Special focus is given to marine application environments: offshore platforms, passenger vessels, and naval ships.

As maritime environmental regulations tighten, choosing the right wastewater treatment technology is more critical than ever. A membrane bioreactor provides a compact, efficient, and environmentally responsible solution – ideal for ships and offshore platforms that require IMO-compliant wastewater management.

What is a membrane bioreactor?

A membrane bioreactor (MBR) combines biological treatment with membrane filtration to remove organic matter, pathogens, and even microplastics from black and grey water. This technology replaces traditional clarification and disinfection processes by integrating ultrafiltration directly into the biological treatment system.

This is why membrane bioreactor technology is increasingly selected for both newbuilds and retrofit installations – particularly in applications requiring a compact footprint, high effluent quality, operational reliability, and compliance with stringent environmental regulations.

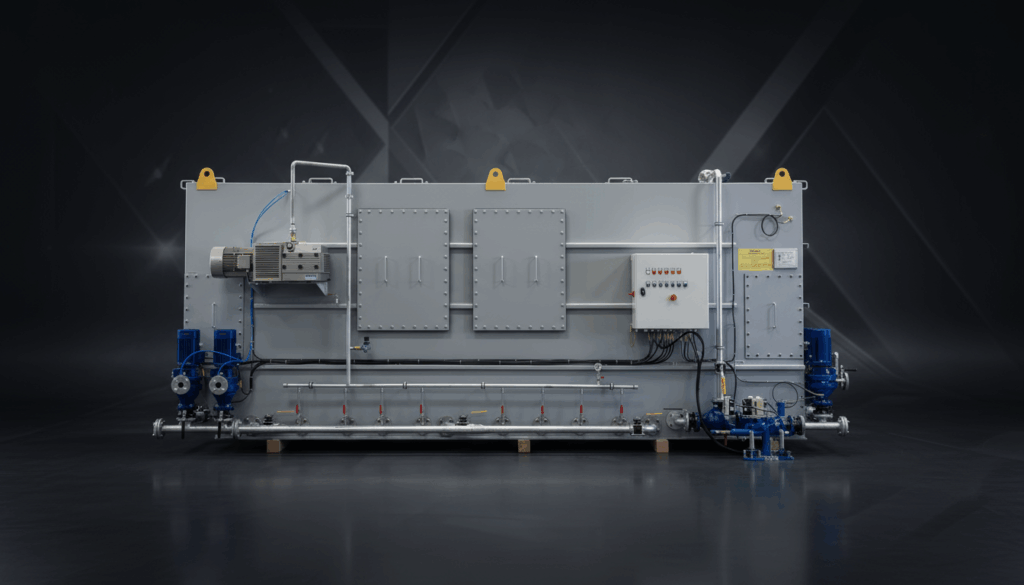

G&O Bioreactors delivers one of the most robust membrane bioreactor systems on the market. Our units are built using European components and engineered for demanding marine environments.

Key features include:

- Ultrafiltration membranes that remove solids, bacteria, and microplastics

- A chemical-free, biological treatment process

- Modular construction for simple retrofit or newbuild integration

- Compliance with international standards (IMO, DNV, UK MER, Chile)

- Black and grey water treatment in a single unit

Where other systems rely on chemicals and PLC-based control, our membrane bioreactor operates simply and reliably – reducing both installation complexity and long-term maintenance costs.

Comparison: Membrane Bioreactor System vs. Conventional Wastewater Treatment

| Feature | Membrane Bioreactor System | Conventional System |

| Effluent quality | Significantly cleaner effluent, suitable for sensitive marine discharge areas | Lower effluent quality, may require chemical disinfection |

| Chemical use | No chemical dosing (e.g. chlorine) required | Often relies on chlorine or other chemicals for disinfection |

| System footprint | Compact design – ideal for space-constrained vessels | Requires larger tanks and more space |

| Performance stability | Stable under varying load conditions | Performance can vary depending on load and chemical balance |

| System complexity | No need for settling tanks – simplified installation and operation | Typically includes clarifiers, settling tanks and chemical dosing units |

Core Design Elements of G&O’s Membrane Bioreactor System

Biological treatment and decoupled design

In G&O’s system, high mixed liquor concentrations are maintained without compromising process control. By separating SRT and HRT, engineers can optimise organic load removal independently of volumetric capacity, enabling a smaller system footprint and greater design flexibility.

Ultrafiltration and solids separation

The physical barrier created by ultrafiltration membranes removes bacteria, suspended solids, and microplastics. Unlike clarifiers, membrane performance is independent of sludge settleability, offering consistent effluent quality and improved pathogen retention. Log Removal Values (LRVs) for viruses and coliforms are significantly improved.

Fouling management

Membrane fouling – biological, organic or inorganic – is mitigated via a combination of air scouring, relaxation cycles, and optional chemical cleaning. Our system design reduces TMP rise and prolongs membrane lifespan, maintaining stable flux over time.

Marine Application Scenarios

Offshore Installations

Offshore platforms and FPSOs require systems that can handle load variability, intermittent operation, and space restrictions. The MBR’s high MLSS tolerance and compact modularity make it well suited for such conditions, while ensuring compliance with IMO and regional effluent standards.

Passenger Vessels

Cruise ships and ferries operate under strict discharge controls in coastal zones. MBR systems consistently deliver superior TSS and coliform removal without chemical handling. This reduces crew workload, simplifies operation, and enhances compliance assurance.

Navies

Military and defence vessels impose strict design criteria around reliability, noise levels, and footprint. G&O’s membrane bioreactor systems address these needs by offering:

- Silent operation and low vibration design

- High redundancy through modular layout

- Compatibility with varied operational profiles, from continuous deployment to lay-up

Membrane modules can be serviced individually, and the system can be fully integrated into platform-wide monitoring systems using standard marine protocols.

Retrofit Projects

Retrofit scenarios often involve complex spatial constraints, legacy piping, and integration with existing vessel infrastructure. G&O’s modular membrane bioreactor systems are engineered for minimal disruption during installation. The system’s compact footprint, combined with custom layout flexibility, allows for efficient deployment within existing compartments.

Engineering for longevity and compliance

G&O Bioreactors are engineered with lifecycle value in mind. The system’s lower sludge yield and reduced chemical consumption translate to lower OPEX. All systems are built from corrosion-resistant materials and high-grade European components, ensuring durability even under harsh marine conditions.

By investing in membrane bioreactor technology, operators gain a future-proof platform capable of adapting to tightening discharge regulations, reducing operational disruptions, and delivering stable performance over decades.