Introduction to Wastewater Treatment Processes

Effective management of wastewater holds great importance due to its direct impact on marine ecosystems and human health. Wastewater generated aboard ships, vessels, and offshore installations necessitates specialised treatment to mitigate environmental hazards and adhere to stringent regulatory standards.

In the marine industry, various wastewater treatment methods are employed, each tailored to specific vessel types, offshore facilities, or environmental regulations. Common techniques encompass physical processes like sedimentation and filtration, chemical treatments involving disinfection and coagulation, and natural sewage treatment methods and biological processes such as activated sludge treatment or membrane bioreactors.

“G&O Bioreactors offer an eco-friendly alternative that leverage the inherent capabilities of natural elements to purify wastewater” says Head of Sales G&O Bioreactors, Thomas Højbo Hansen, “ the core operation within our reactors, whether conventional or advanced, relies entirely on a 100% biological process, devoid of dilution or consumables. Wastewater undergoes a series of chambers where naturally occurring bacteria work to biologically cleanse it. These bacteria utilise oxygen to convert sewage into CO2 and water, leaving behind a minimal amount of sludge. This entire process remains completely devoid of synthetic chemicals”.

Unlike chemical-based systems employed by other wastewater treatments, which often leave residual traces of harsh chemicals in the treated water, a biological process offers a superior alternative and demonstrates fundamental sustainability. It requires lower energy consumption and offers cost-effective solutions without compromising efficiency.

The conventional bioreactor represents an entirely biological treatment system that incorporates a fixed biofilm in conjunction with UV treatment, providing a sustainable and eco-friendly solution. Capable of managing all grey and black water generated from vessels or offshore facilities, this system operates without the necessity for filters, dilution, or chemicals during its regular treatment process.

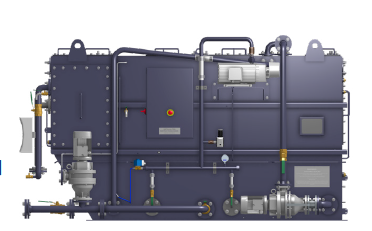

“In our advanced bioreactor, black and grey wastewater enters the bioreactor’s pre-treatment tank via a macerator equipped with a four-knife cutting system, which effectively reduces particle sizes to an ideal level for the following membrane filtration process. From there, the water is forced into the filtration tank where a process of nitrification removes nitrogen while filtration eliminates phosphorus particles and E.Coli contaminants”, Thomas Højbo Hansen explains, and finishes: “ After these treatment stages, the cleansed water is drawn out using a permeate pump, passing through the membrane filter system. Once it meets the required standards, the treated water is then safely discharged overboard”.

G&O bioreactors have more than 1,000 installations, catering to a wide range of operations, from offshore drilling rigs and passenger vessels to small tugboats and land installations.

Stay updated

Sign up to our newsletter and receive more information about the latest news in G&O Bioreactors and G&O Maritime Group