Passenger Vessels

Advanced wastewater treatment for demanding regulations

Passenger vessels face some of the strictest wastewater treatment requirements in the maritime industry, particularly when operating in Special Areas like the Baltic Sea, governed under IMO MEPC 227(64), section 4.2. At G&O Bioreactors, we deliver advanced membrane systems engineered to meet and exceed these standards.

IMO & Special Area Compliance

Since 2016, regulations have required effective removal of nutrients like phosphorus and nitrogen to prevent environmental damage. G&O was among the first to obtain approvals under these tightened rules, and we continue to adapt as more areas adopt similar requirements.

Tailored Systems for Passenger Operations

Our solutions are specifically engineered for the unique challenges of passenger vessels:

- Flexible integration: We work closely with ship designers and owners to minimise installation footprints.

- Smart tank solutions: Our systems can be built directly into the vessel’s structural tanks, reducing the need for additional engine room space.

Compatibility Without Compromise

We frequently meet concerns about system compatibility. It’s a common misconception that collection systems (e.g., toilets and vacuum systems) must come from the same provider as the treatment plant. In reality, G&O systems are designed to interface with any brand of collection system.

For those seeking a more complete setup, G&O can also supply integrated grease separation and intermediate pump tanks, ensuring reliable downstream flow to the treatment plant.

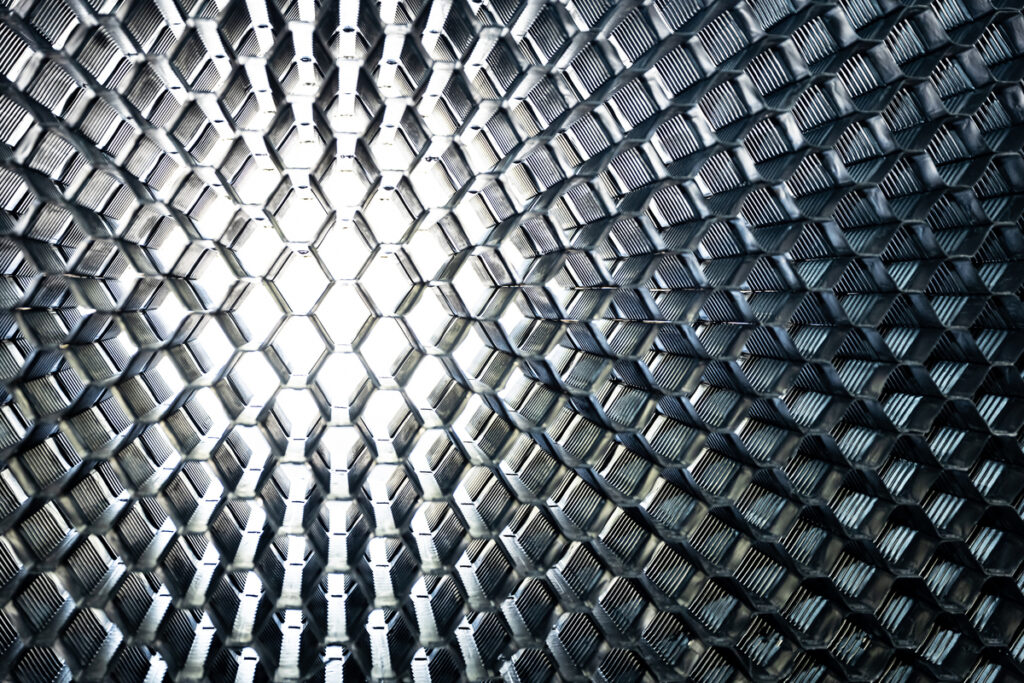

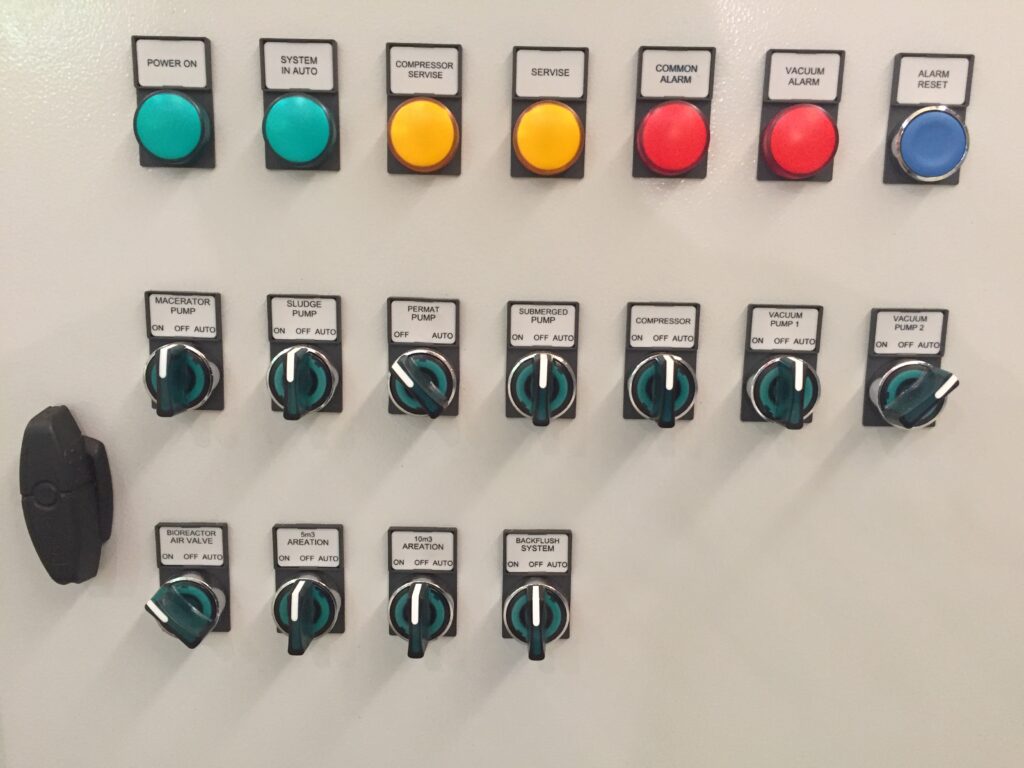

In contrast to many conventional wastewater treatment systems, G&O membrane Bioreactors operate with a controlled flow through our installed membrane, which, combined with an integrated backflush system, ensures optimal lifetime of the membrane. We offer simplified installation, which adds to reducing both the vessel design phase, commissioning, and maintenance costs.

Advanced Bioreactors from G&O also remove the environmental and operational risks associated with chlorine-based disinfection systems, offering consistent uptime, fewer alarms, and ease of mind for day-to-day maintenance for the crew onboard. G&O solutions reduce crew workload and hands-on engineering for the majority of vessels, a substantial saving in both time and total cost of ownership.

Global Service and Support

All Bioreactors deliveries include full lifecycle support:

- Worldwide network of authorised service partners

- 24/7 direct service availability

- Genuine G&O bioreactors spare parts with 12-month warranty

- Training for onboard personnel

- Optional remote diagnostics