G&O Bioreactor

Conventional bioreactor

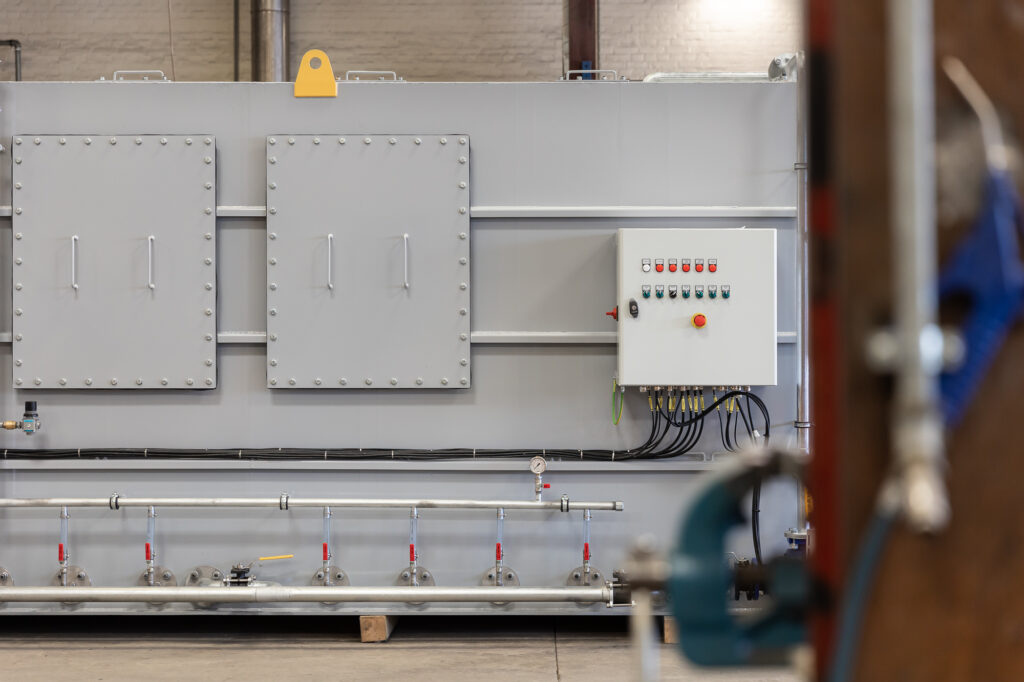

Efficient, compliant, and easy-to-operate biological wastewater treatment

The G&O Conventional Bioreactor offers a proven, chemical-free solution for treating black and grey water – ensuring IMO compliance and reliable performance with minimal complexity.

Biological cleaning, removing E.coli

The bioreactor is a 100% biological treatment system,

which uses a fixed biofilm combined with UV treatment for

a sustainable solution. The system can handle all grey and

black water from any vessel or offshore facility with no need

for filters, dilution or chemicals during normal treatment.

Our systems lives up to IMO requirements.

Discover the simplicity behind reliable wastewater treatment

Our Conventional Bioreactor is designed for shipowners and operators seeking a robust, low-maintenance biological wastewater treatment solution. In this video, you’ll get a closer look at how our system works.

How it works

The fundamental process used in our bioreactors is 100% biological. There is no dilution or consumables. Waste water is led through several chambers and in the process is cleaned biologically with naturally occurring bacteria. The bacteria use oxygen to convert sewage into CO2 and water, leaving a small residue of sludge.

Before going into the cleaned water tank ready for discharge, the water passes through a UV filter to kill any remaining bacteria, including E.coli. The process is entirely free of manmade chemicals.

Systems for new builds

We deliver system for new build vessels of any type and size from navy ships to large passenger ships.

Retrofitted systems

We can custom build bioreactors and fit them into even the tightest spaces on existing vessels.

Design options

- Available in coated black steel and coated or uncoated stainless steel

- Work with both gravity and vacuum systems

- Vacuum equipment, grease separation and sludge handling systems available

- CE and ATEX systems available

- Custom designed systems e.g. where space limitations disqualify the use of standard systems

- Tailor-made split units e.g. for retrofit projects

Simple and easily maintained

- Designed for easy operation and maintenance

- Easy operation with minimal manual operation

- Built-in cleaned water tank and inlet tank

- Danish design

- Fitted with quality components from European suppliers

- Low power consumption

We can deliver auxiliary solutions or connect with existing systems

Grease separating units

A well-dimensioned grease separation is essential for a well-functioning water treatment system for both black and grey water. Besides reducing the organic load of the treatment plant, it also prevents grease from building up in the vessel tanks and piping.

Vacuum collection solutions

The majority of treatment systems we deliver are delivered with a G&O vacuum collection integrated into the system control and structure.

Sludge handling solutions

Sludge handling procedures will become a requirement in future marine regulations. We can dewater the sludge to minimise the volume of tanks required for storing sludge, returning water to the sewage treatment plant for processing before discharge.

Sludge can be incinerated or disposed as solid waste.

Technical specifications

| Bioreactor type | Hydraulic load (M3/d) | Organic load (BOD5 kg/d) |

| BR01850BG | 1.85 | 0.75 |

| BR03700BG | 3.70 | 1.50 |

| BR05550BG | 5.55 | 2.25 |

| BR07400BG | 7.40 | 3.00 |

| BR09250BG | 9.25 | 3.75 |

| BR11100BG | 11.10 | 4.50 |

| BR14800BG | 14.80 | 6.00 |

| BR18500BG | 18.50 | 7.50 |

| BR23125BG | 23.13 | 9.38 |

| BR27750BG | 27.75 | 11.25 |

| BR37000BG | 37.00 | 15.00 |

| BR46250BG | 46.25 | 18.75 |

| BR55500BG | 55.50 | 22.50 |

| BR64750BG | 64.75 | 26.25 |

| BR74000BG | 74.00 | 30.00 |