G&O Bioreactor Split Unit

With the ever-growing focus from authorities and ship owners on effluent quality, a flexible approach for tailoring sewage treatment plants is called for when retrofitting an older installation or upgrading for more people on board.

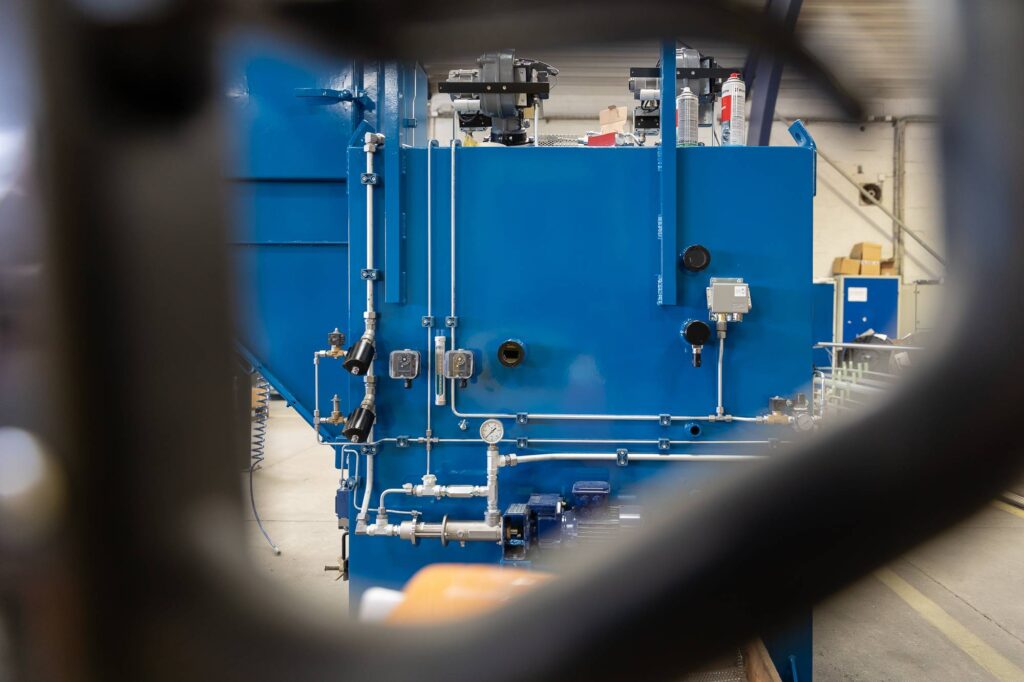

Another split unit from G&O Bioreactors

A complete biological sewage treatment plant is delivered in sections of no more than 1000×1000 mm (each) to pass a narrow engine room hatch on deck and assembled deep inside in the engine room of an FSO 20, km from shore in Brazil waters, during the vessel’s operation. This was the task handed over to GOMG in the middle of the global pandemic in September 2020. What at first seemed like an impossible situation is now solved. However, it was not the first time for the same client, but the 3rd time. However, the unit has now successfully passed third-party inspections and Factory acceptance test.

Looks can be deceiving

At first glance, the unit may seem incomplete regarding cable standards, and less appealing to the eye. However, the unit is only assembled for testing purposes and then completely disassembled to be shipped in pieces. Below, you can see photos of the unit fully assembled and ready for testing, and when it is packed and ready for shipping.

Combining the design experience within Gertsen & Olufsen A/S as well as utilising the workforce synergies within Atlas Incinerators and local Danish and international equipment, suppliers ensured that a unique product was delivered this week from Gertsen & Olufsen and Atlas Incinerators.

Now, the task at hand for the client and crew is to assemble the unit onboard the prepared base frames, after which Gertsen & Olufsen will arrive in due time to verify installation and conduct commissioning.

A G&O trademark

Customisation is not new to G&O Bioreactors. In fact, we do it continuously on both small and big scales.

Split sectional units have been delivered from GOMG throughout the years, but it is not in the everyday work. The task is resource-demanding; there are many engineering hours that require strong and focused project management. However, GOMG is ready to rise to the task.

With the ever-growing focus from authorities and ship owners on effluent quality, a flexible approach for tailoring sewage treatment plants is called for when retrofitting an older installation or upgrading for more people on board.

G&O Bioreactors has dedicated itself over the last several years to build a strong global brand, providing excellent solutions to sewage treatment, in tight cooperation with owners and vessel managers. This time was no different.

About the Bioreactor

A G&O Bioreactor is capable of handling grey and black wastewater and can be implemented in remote locations, seagoing vessels, and the offshore sector.

The G&O Bioreactor system provides an excellent growth environment for the bacteria media. By using the Matrix, the plant obtains a 125 times larger internal surface where the bacteria media can adhere compared to any traditional Active Sludge Plant/tank.

Information about the plant

| Type | Bioreactor BR27750 |

| Hydraulic Load | 27,75 m3/d |

| Organic Load | 11,25 kg BOD5/d |

| Max. PE/POB | 120-150 Persons |

| Material | AISI 316L |

| Sections | 9 |

The Bioreactor is approved following IMO MEPC 227(64) as well as type-approved and certified by DNV-GL.

Stay updated

Sign up to our newsletter and receive more information about the latest news in G&O Bioreactors and G&O Maritime Group